Talk about a field that is exploding with innovation potential! Two members of the PVD Products team recently had the chance to attend a workshop at the National Institute of Standards and Technology (NIST) on accelerated discovery for energy materials. The aim of the day was to gather ideas from the research community on how to use artificial intelligence (AI) and machine learning (ML) to more quickly arrive at novel complex materials. Huge benefits are possible from materials that can increase energy collection efficiency (think solar cells, for example) or energy storage density (think high capacity lithium ion batteries). This quest intersects in a big way with thin film deposition, which is what drew us to check it out.

Discovering a Smarter Approach to Combinatorial Deposition

Combinatorial thin film deposition, or simply “combi,” is a family of methods for depositing many films of various compositions or a single film with a range of compositions in one experiment. It is possible to create a “library” of hundreds or thousands of compositions in one run. This is why the broader term High Throughput Experimentation (HTE) is applied. But the task complexity grows geometrically – think of how one would explore even three- or four- component films selected from the ninety-something chemical elements. No one has enough resources to check every possible composition combination, which limits the throughput.

Examining the Potential of AI in Combinatorial Deposition

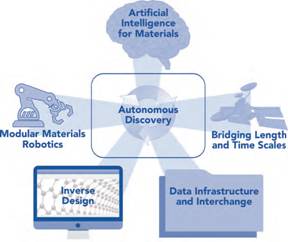

The workshop addressed this issue surrounding combi. What if instead of making and measuring a thousand candidates for, say, a thermoelectric material, we could work smarter? The speakers in the morning session discussed many possible avenues for AI-driven autonomous discovery. The proposed process shed light on the following:

The workshop addressed this issue surrounding combi. What if instead of making and measuring a thousand candidates for, say, a thermoelectric material, we could work smarter? The speakers in the morning session discussed many possible avenues for AI-driven autonomous discovery. The proposed process shed light on the following:

- Advances in computer technology make it possible to do large numbers of theoretical predictions of material behavior.

- A human-defined goal, like higher thermoelectric efficiency, is provided to an AI that manages simulations and suggests a small library to test.

- A connected combi deposition system is fed these suggestions and makes the films.

- Robotic handling transfers the samples for measurements of the properties of this set to determine figure of merit across the library.

- The measurement system feeds these results back to the AI, which can then suggest the next set of films to measure.

By “closing the loop”, the experiments can iterate autonomously toward a solution. It reminds us of our GPS app, which, in just three seconds, offered to guide us from where we sit in our office near Boston to Laguna Beach to catch some good sun. Now we just need the car to drive us there on its own!

Discussing How to Achieve these AI Solutions

In the afternoon we broke into groups to discuss four aspects of the problem. In the instrumentation session, our favorite topic, we discussed NIST’s “collaboratory” efforts – how could we structure a network of facilities that could offer the full range of synthesis and measurement tools that anyone could access to do HTE?

Rather than a disjointed set of hardware tools, the collaboratory would have distributed resources with central guidance, managed equipment access, shared computational and data storage capabilities. New data sharing models would provide access to past results in a standard format, so that everyone in the community could efficiently build off past discoveries. To continue our example above, the AI might be hosted at a national lab and communicate its most promising thermoelectric materials to a combi tool in another state, the synthesized samples then being shipped and tracked to one or more remote analytical labs for characterization – finally reporting the results back to the AI. By reducing the barriers to entry into combi work, more participants could discover more high-value materials.

A lot of innovation is needed to fully realize this concept. PVD Products has offered combi deposition tools for many years, and we constantly look to innovate and grow in order to help our customers succeed. We look forward to using our intelligence in custom tool development to help accelerate materials discovery.

To learn more about combi deposition tools, download our free eBook:

Combinatorial Deposition for Materials Development

*photo credit: “Six Grand Goals of the Materials Acceleration Platform.” (Credit: Report of the Clean Energy Materials Innovation Challenge Expert Workshop, January 2018)

Leave a Comment