Why Choose Custom Deposition Systems?

Choosing a custom deposition system is often a necessity when standard, off-the-shelf equipment fails to meet the specific technical demands of advanced research or high-end manufacturing.

Standard units frequently lack the flexibility to accommodate unique substrate sizes ranging from 5mm samples to 300mm wafers or specialized roll-to-roll processing.

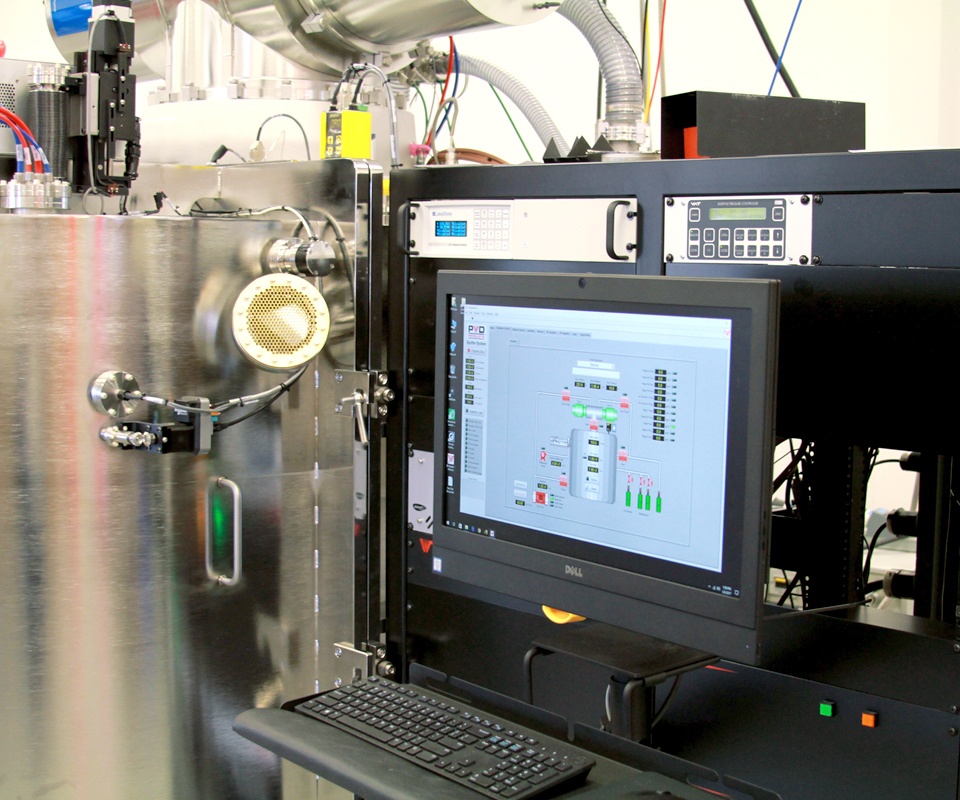

Furthermore, custom engineering is essential for developing complex multi-layer combinatorial coatings that require precise control, or for integrating multiple deposition techniques, such as PLD, sputtering, and evaporation, into a single, cohesive system.

Beyond the technical process, custom systems and equipment address specific environmental variables like unique gas compositions, extreme pressure ranges, and precise temperature requirements that standard models cannot support.

They also ensure seamless integration with a facility’s existing technology and can be designed to fit within the rigid space constraints of established cleanrooms or laboratories.

PVD Products specializes in these custom-engineered thin film deposition systems, serving the diverse needs of researchers and manufacturers across North America and around the world.