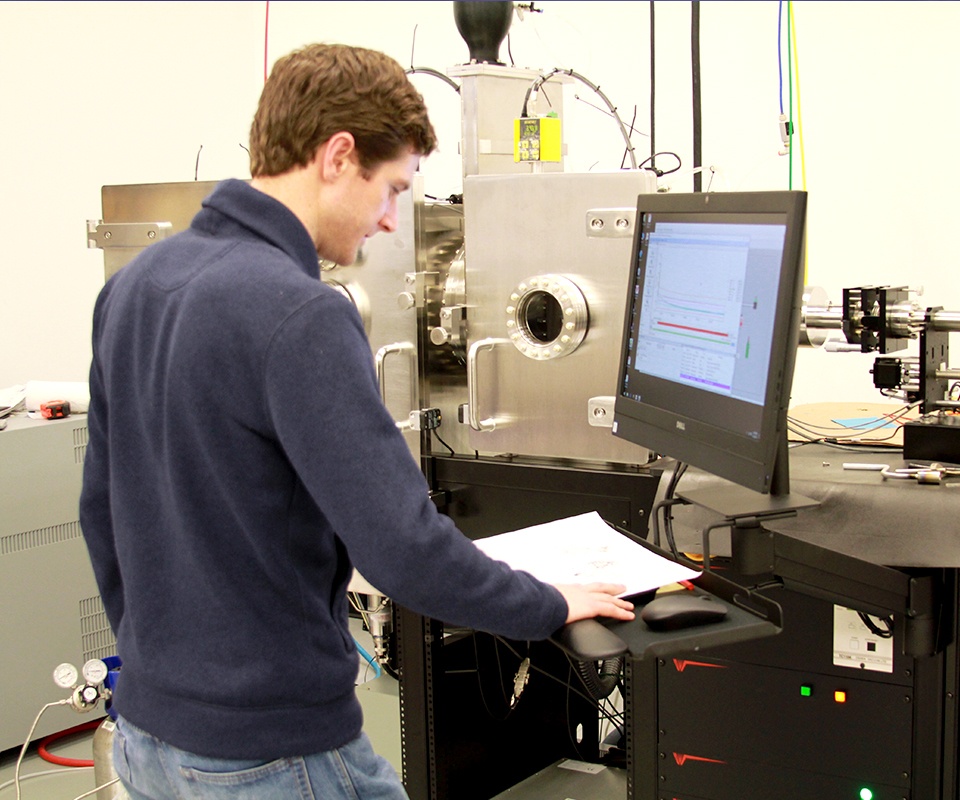

PVD Products provides thin film deposition services. We can deposit thin films using magnetron sputtering, PLD and electron beam evaporation on an as-needed basis for R&D applications. We utilize in-house equipment that can be modified in some cases to meet the customer's needs. We have an in-house PLD/MBE 2300 system with both PLD and magnetron sputtering capability for 2-inch diameter wafers. Substrate heating to 950ºC is readily available. We also have an in-house sputtering tool capable of handling wafers up to 6 inches in diameter. We have an electron beam evaporation system capable of coating up to eight six-inch wafers simultaneously. We have a reel-to-reel sputtering system for depositing continuously on moving tape or wire for process development or pilot production.

Upgrades & Maintenance

PVD is committed to your unique deposition requirements, not just before delivery, but also during and after. Talk with us to explore retrofitting or additional options that can expand your capabilities.

Thin Film Deposition

PVD Products provides thin film deposition services with magnetron sputtering for R&D applications such as combinatorial deposition or new materials development.

Deposition System Design

PVD Products provides complete 3-D Solid Models of Custom Deposition System Designs as a service for your prototype or custom thin film deposition or vacuum chamber needs. These services include: mechanical design using Solid Works electronics design for motion control, power distribution, data acquisition, and cabling software for system control such as LabVIEW.

Deposition Software Design

A customized vacuum deposition system requires customized software to control the hardware, acquire the data, and interface with existing laboratory equipment. For every system we build, we work with you to design a software package that meets your needs, current and future.