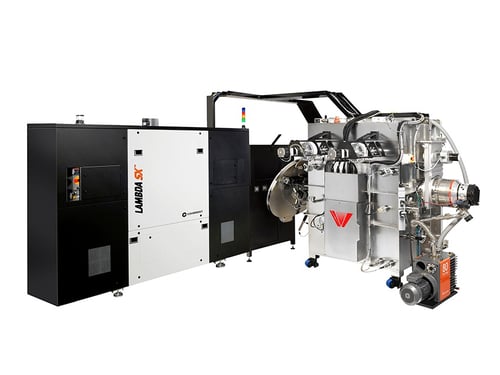

PVD Products delivers a comprehensive portfolio of coated conductor deposition systems engineered for high-temperature superconducting tape and wire manufacturing. These advanced platforms support multiple thin-film processes, including pulsed laser deposition (PLD), sputtering, evaporation, and ion beam–assisted technologies, enabling precise control over film quality and performance.

PVD Products is the world leader in coated conductor deposition equipment, specializing in reel-to-reel (R2R) systems for high-temperature superconducting (HTS) wire production. Our comprehensive portfolio includes pulsed laser deposition (PLD), magnetron sputtering, ion beam assisted deposition (IBAD), and evaporation systems designed specifically for YBCO and REBCO superconductor manufacturing.

With decades of expertise in thin film deposition technology, we deliver complete turnkey solutions for buffer layer deposition, epitaxial growth, and HTS film fabrication. Our systems support both R&D scale development and high-volume production environments, serving leading superconductor manufacturers, national laboratories, and research institutions worldwide.

PVD Products manufactures advanced reel-to-reel magnetron sputtering systems optimized for coated conductor buffer layer deposition. Our sputtering platforms deliver exceptional uniformity and throughput for both reactive and metal deposition processes.

Our buffer layer expertise includes CeO2, LaMnO3, LSMO, MgO homo-epitaxial growth with ion beam assist, Ag stabilizer layers, and custom multi-layer stacks for specific applications.

Our sputtering systems feature AC, DC, and RF magnetron sources with multiple cathodes per chamber, reactive sputtering with precise oxygen control, cylindrical rotating targets, and advanced gas distribution for compositional uniformity.

Ion beam assisted deposition (IBAD) is critical for deposition of HTS materials and buffer layers. PVD Products offers complete IBAD solutions combining evaporation or sputtering sources with low-energy ion beam bombardment for biaxial texture development.

Our IBAD-MgO technology delivers in-plane alignment better than 3° FWHM, with tunable ion beam energy (100-1500 eV) and incident angle (40-55°) for optimal texture evolution.

The process enables HTS deposition on low-cost flexible metal substrates, eliminating expensive single-crystal or RABiTS substrates while maintaining high performance.

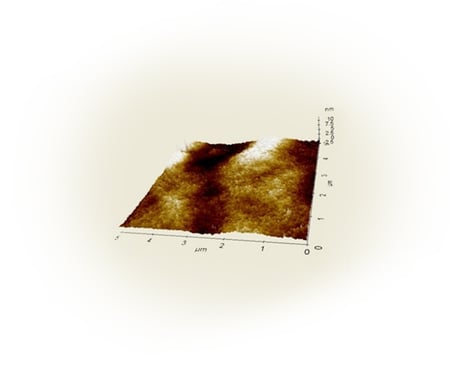

Developed in partnership with iBeam Materials, our solution deposition planarization systems address a critical challenge in coated conductor manufacturing: achieving the ultra-smooth surfaces required for high-quality epitaxial buffer layer growth.

The quality of HTS film stacks depends on exceptional surface smoothness beneath the biaxially textured buffer layer, as even minor substrate roughness can disrupt epitaxial growth and significantly reduce critical current performance.

The coated conductor typically starts with a 10-100 mm wide Hastelloy tape, followed by a yttria barrier layer, an oriented MgO nucleation layer, a YBCO high Tc film, and a thick overcoat of Ag. The reel-to-reel system provides continuous operation for long-length tapes with uniform thickness control across the full tape width.

Beyond complete turnkey systems, PVD Products supplies individual components and subsystems for customers building or upgrading their own coated conductor manufacturing infrastructure.

Our portfolio includes substrate heaters up to 1000°C with excellent uniformity, XYθ target manipulators with automated rotation, Intelligent Window systems that extend maintenance intervals, and optimized optical trains for PLD applications.

We provide precision tape transport systems for 4-100mm width tapes, custom reel-to-reel vacuum chambers with UHV capability, and PLC-based control systems with recipe management and remote monitoring.

All components are specifically designed for long tape lengths, high-temperature processing, and reactive gas environments essential to coated conductor applications.