Our very popular low-cost Nano PLD system is designed for researchers interested in small-scale thin film materials development and is high pressure RHEED compatible. This system can handle wafers up to 2 inches (50.4 mm) in diameter as well as smaller samples. Though this is our most basic system, the Nano PLD doesn’t compromise on many of the key features of our larger area and more sophisticated PLD 3000 and PLD 5000 systems, as well as the PLD/MBE series. There are many options that come with the Nano PLD system to provide a very functional PLD tool at a reasonable price.

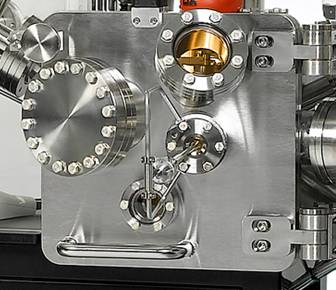

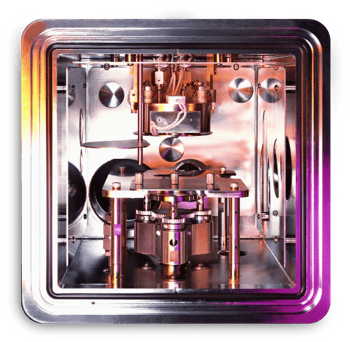

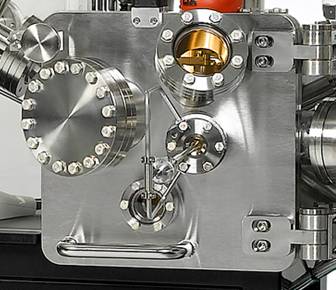

The Nano PLD system is based on our user-friendly rectangular box chamber design that provides ease of transfer for both substrates and targets through the large front-mounted hinged door. The turbo pump is safely mounted on the back wall, where substrates or film deposits cannot fall into it. The target manipulator uses a pair of long-life Ferro fluidic rotary feedthroughs. Our substrate heater uses our special IR lamps with a water-cooled housing. The unit has a small footprint and can operate off a laptop computer. Systems can include a variety of lasers such as an excimer or Nd:YAG.

Inside the Nano PLD chamber. Note the ease of access through the large front door. The system can support an optional magnetron sputter source, ion source, atom source, or effusion cell.

The Nano PLD System comes with a wide variety of options, including:

A wide variety of Nano PLD wafer holders are available for various size substrates.

We offer one 2-inch diameter substrate or multiple small samples. Shown in the photo are three sample holders, one handles a 2-inch (50.4-mm) diameter wafer, one holds four 1-cm square samples, and one holds a single 1-inch square sample. Many other sample holders are readily available.

Nano PLD wafer holders for various size substrates

Our heaters can heat non-transparent substrates to 900°C (in oxygen) and transparent substrates to 850°C WITHOUT the use of silver paste. We are quoting substrate temperatures, not heater element temperatures.

The Nano PLD system comes with a complete optical train to produce a static plume within the chamber. Optional laser beam rastering to enhance film uniformity and the utilization of target material can also be provided. The optical train includes a pneumatic assembly to open and close the excimer laser shutter without having to open the hinged door on the transparent laser-safe enclosure. Also included are a beam shaping aperture set, multiple mirrors mounted on kinematic mirror mounts for fine positioning of the laser beam within the chamber, and a focus lens. All viewports on the chamber include laser-safe covers.

Systems come standard with 248 nm (KrF) or 266 nm (Nd:YAG). Other wavelengths are available on request.

PVD optical train with a pneumatic actuator used to open the laser shutter via computer control, along with an XY aperture to adjust beam size, a focus lens, and mirror mounts. Also shown is the raster actuator and Intelligent Window assembly.

The Nano PLD system comes with an IR lamp based heater capable of heating silicon and other non-transparent substrates to 950°C and transparent substrates to 850°C. (Note: PVD is quoting substrate temperatures, not heating element temperatures as there is a large difference in temperature between the element and the substrate on all heaters.) The heater can handle 2-inch diameter substrates or multiple smaller samples per the customer requirements (i.e. a holder for four 1-cm square samples). Using a Ferro fluidic rotary feedthrough, substrates can be rotated via computer at rates up to 40 RPM. The substrate is positioned 75 mm from the target surface. The heater can be mounted to an optional large motorized Z-stage, providing computer controlled target-to substrate distances varying from about 50 to 100 mm. The open architecture of our IR lamp heater is ideal for in-situ analysis using HP RHEED, and alternative deposition sources such as magnetron sputtering, effusion cells, ozone generators, atom or ion sources, etc. One of these deposition sources can be mounted on the 6” CF flange on the side of the Nano PLD chamber.

Nano PLD non-contact substrate heater with optional rotation and pneumatic shutter assembly

Either four 2-inch diameter targets (maximum diameter) or eight 1-inch diameter targets are available. Other arrangements may be available upon request.

The target manipulator includes a pair of Ferro fluidic rotary feedthroughs and computer controlled motors. All target motion, rotation, indexing, and toggling, if required, are included in the provided software. The Ferro fluidic rotary feedthroughs provide years of trouble-free operation and will not fatigue over time the way bellows sealed feedthroughs do.

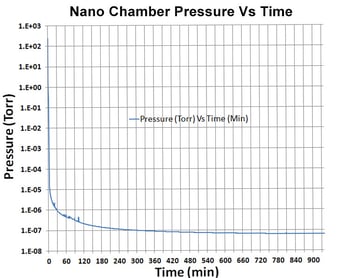

Target carousel with four 2-inch diameter targets

5 x 10-7 Torr base pressure (guaranteed). With our optional dual-wafer load lock, the base pressure is reduced to below 5 x 10-8 Torr. The system utilizes a Pfeiffer HiPace 300 turbo pump, one MFC, an ion gauge and two Convectron gauges. The base unit includes an all pneumatic valve package, which includes a vent and over-pressure relief valve. Below is a typical pump-down curve for a clean, dry chamber with no targets present. Pressures below 5 x 10-7 are achieved in about 1 hour.

Nano chamber pressure vs. time

A set of programmable shutters holds masks during combinatorial thin film deposition.

A 10-inch square box-style chamber with a front-mounted hinged door provides quick and easy substrate and target changes. The chamber includes ports to handle the addition of a 2-inch magnetron sputter source with shutter, or an ion beam source. The chamber also includes ports for target and substrate viewing, high pressure RHEED, emission or absorption spectroscopy, and a port for the addition of an optional load lock, etc.

Nano PLD chamber front door with two viewports, RHEED screen port, and a port with a wobble stick for the optional load lock.

"PVD is genuinely interested in helping me advance my capabilities for thin film deposition with an instrument that fits my applications best."