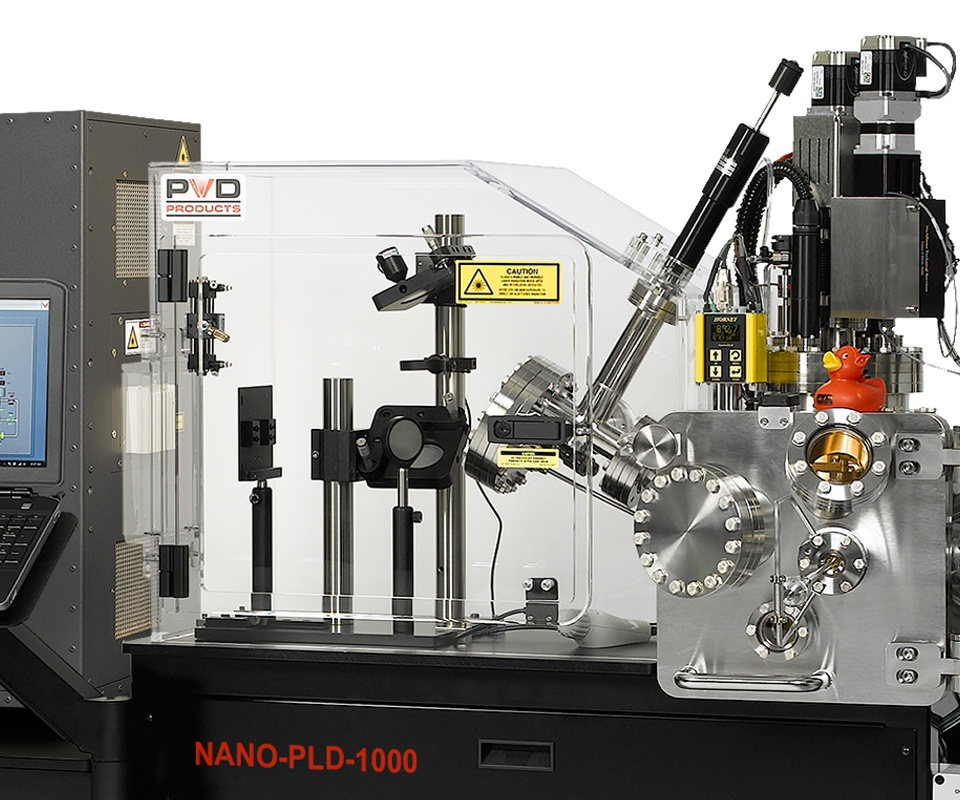

All of our PLD systems come with a complete optical train. This includes an optical breadboard positioned on the surface of one of the electronic racks or frame. The optical train consists of a focus lens, mirror set, kinematic mirror mounts, and PVD’s Intelligent Window (optional on the Nano PLD systems). All the optical components are AR coated for either 248 nm (KrF) or 193 nm (ArF). Other wavelengths are available as well. A computer is supplied to control the rastering of one of the kinematic mirror mounts so that the laser can be scrolled completely across a target diameter. As noted above, a constant fluence optical train is supplied with our larger PLD systems. Here the focus lens position is slaved to that of the raster mirror so that the beam path length does not change as the laser beam is rastered across the large diameter targets.

The optical train is completely enclosed in a UV blocking laser tight box that provides both eye protection as well as an excellent dust cover. The box is sufficiently airtight so that it can be purged with nitrogen to minimize ozone formation when using 193 nm (ArF) excimer laser radiation. A large hinged door on the front of the box allows for easy adjustment of all the optical components. Furthermore, if the excimer laser is purchased from PVD Products, most systems will include a pneumatic shutter assembly which will open and close the excimer laser shutter via computer control. Thus, the box does not need to be opened to complete this task.

Optical trains can be simple breadboard assemblies or more complicated units as needed. Shown here is a complete beam delivery system used to take the raw laser beam from the excimer laser and deliver it to a PLD target using one of two entrance windows on the customer’s deposition chamber. It includes a number of beam turning mirrors held in kinematic mirror mounts for fine adjustment of the beam throughout the entire optical train. We use high quality HR coated optics for low loss of laser energy. The entire optical train is enclosed for user safety.

Photo of a Custom PLD Optical train used for beam delivery system in a custom PLD system located at the IBM ARC.

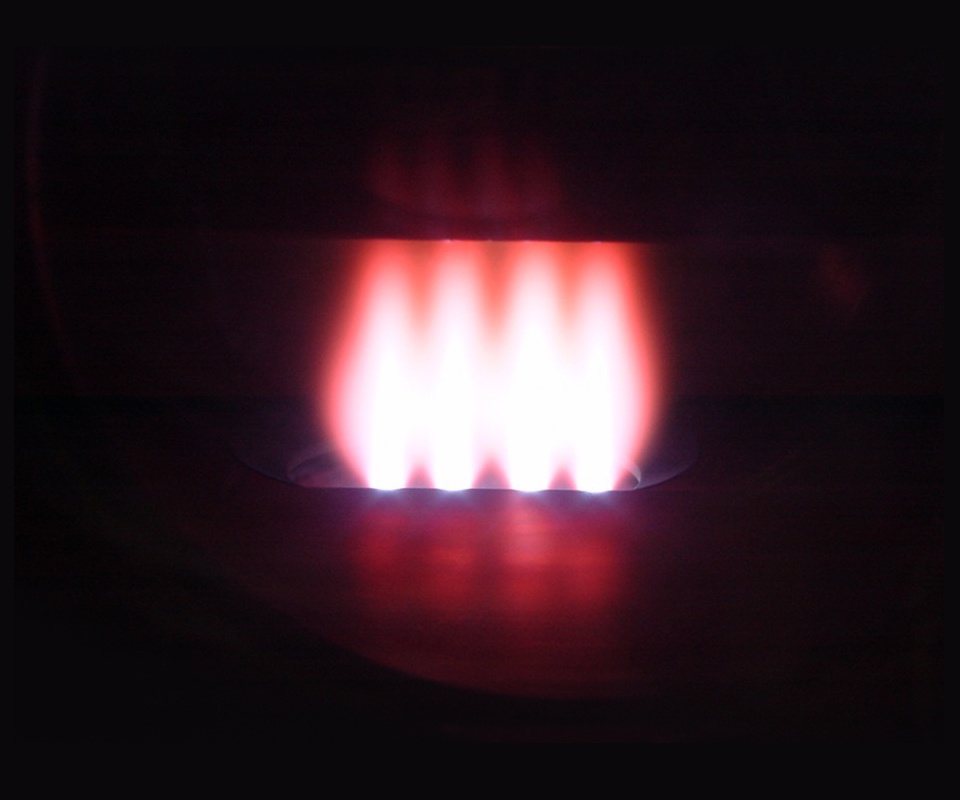

PVD can also provide optical trains for multi-plume deposition in coated conductor PLD applications as seen in the photo below. The number of plumes and plume spacing can all be adjusted with software.

Photo of a PVD Multi-Plume set up for coated conductor applications. The Lambda Steel laser was firing at 200 Hz and our mirror was programed to be slaved with the laser to produce four laser beams across the target surface.