The PLD 8000 system can handle one 8-inch (200-mm) or one 6-inch (150-mm) diameter substrate. It also can hold either nine 2-inch (50-mm) diameter substrates or four 3-inch (75-mm) diameter substrates. Custom substrate configurations are available on request. The PLD 8000 comes with a complete software package and can be used to grow large area multilayer and combinatorial thin films.

950°C (in oxygen) for non-transparent substrates such as silicon, and 850°C for transparent substrates such as sapphire. No thermal paste or bonding required.

±7°C across 8-inch diameter substrate

5 x 10-7 Torr base to 100 mTorr

Three 4-inch diameter targets (maximum diameter). Other configurations such as our unique XYθ manipulator are available on request.

±5% over 90% of 8-inch diameter substrate (using a 9-inch throw)

±2.5 atomic percent over an 8-inch substrate for most materials, such as YBCO, using a 12-inch diameter target, programmable laser beam rastering, and 9-inch throw. (Uniformity of materials with high vapor pressures, such as lithium or lead, may vary significantly depending on deposition parameters.)

System designed for 9-inch (~230 mm) throw. Throw is variable from 7.5 inches (minimum) to 9 inches maximum (affects maximum temperature, thickness, and composition specifications).

~3.8 inches with XYθ target manipulator

Of the laser beam on target: 60°

P < 5 x 10-7 Torr guaranteed, with system at room temperature without targets (5 x 10-8 Torr with load lock and 5 x 10-9 Torr with bake-out options)

Box-style chamber with easy substrate and target changes

248 nm (KrF). Other wavelengths available on request.

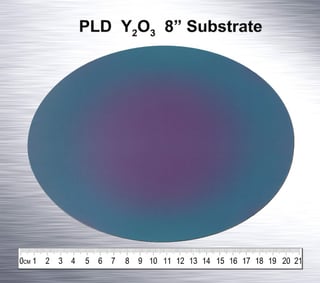

Yttrium oxide film deposited on an 8-inch silicon wafer using pulsed laser deposition. Film thickness uniformity is ± 3.5%.