PVD Products is the world leader in providing complex coated conductor reel-to-reel systems for deposition of HTS materials and buffer layers. We have sold multiple R2R units based on PLD, sputtering, IBAD, and evaporation, and have developed Solution Deposition Planarization products with iBeam Materials.

Many of these systems have been sold to repeat customers. PVD Products is willing to have detailed discussions with potential customers about their current CC requirements. We can help you develop realistic specifications and provide you with a tool to meet your specific deposition requirements.

PVD Products provides a wide variety of PLD coated conductor deposition systems for your specific applications. These include the following:

PVD provides various types of deposition systems for coated conductor applications, including sputtering and evaporation. Applications include:

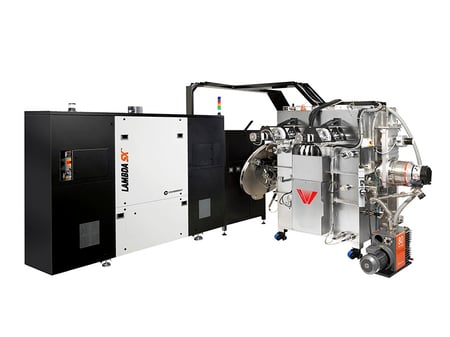

The PLD T1000 coated conductor deposition tool has been designed for both R&D and production of long-length YBCO High Temperature Superconducting tapes and buffer layers to 1 km in length. This computer controlled reel-to-reel system will meet your most demanding deposition requirements and is compatible with a wide variety of metallic tape compositions, widths, and thicknesses. PVD also provides other types of deposition systems for coated-conductor applications, including sputtering and evaporation.