PVD Products provides custom sputtering services for single or multiple small substrates or single wafers with up to 6-inch diameters. Our custom in-house sputter deposition tool can adapt a variety of sputter source heads for single-layer deposition, multilayer deposition, and co-deposition. We can provide DC or RF power sources along with RF substrate bias prior to or during deposition and heating in excess of 300°C. This system is capable of growing metals, oxides, nitrides, carbides, etc.

Our sputter system also allows us to provide combinatorial thin film deposition of multiple test pad samples on one wafer. Using our unique setup, PVD Products can provide co-deposition onto multiple pads of 1 cm square (or other sizes) of varying composition, grown at different substrate temperatures and/or RF bias levels. This tool provides for quick analysis of desired compositions and optimal growth conditions of new materials.

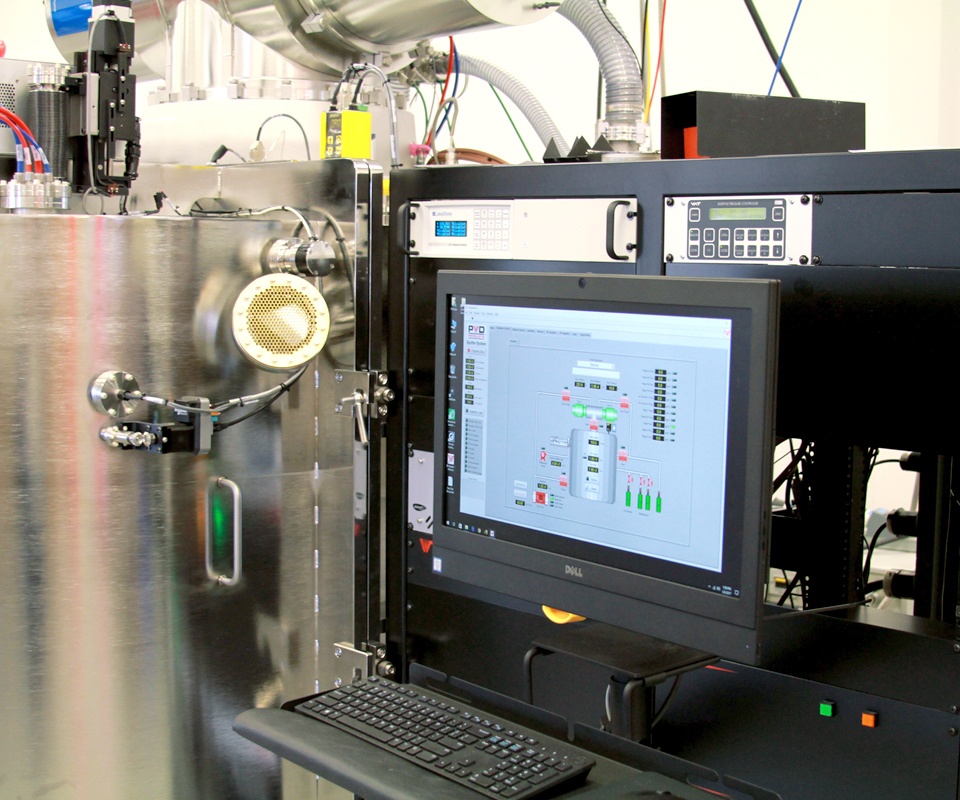

PLD/MBE- 2300 Pulsed Laser and Sputter deposition tool in our service lab

Electron beam deposition tool with ion beam assist in our service lab