At heart, we are a “scientist” company. Our team has a deep understanding of the underlying physics of material science, chemistry, optics, plasmas and electronics. That expertise is what allows us to develop our own components, such as our line of magnetrons, without waiting for the general coating industry to catch up with the latest science. That expertise also enables us to understand a customer’s needs at a fundamental scientific level so that we can develop individual solutions to address their technical challenges.

Here are three instances where our advanced understanding of customer needs enabled us to develop unique modifications that extended the capabilities of their coating systems.

Increasing Throughput for Superconductor Technologies Inc.

The challenge

This superconductor material designer and system manufacturer was using a PVD Products reel-to-reel MgO deposition system. With the desire to increase the tool’s throughput, Superconductor Technologies Inc. came back to our team to see if it would be possible to design upgrades for their system.

The approach

Like we do when upgrading our own machine, we first looked at the original design to assess the customer’s current process. Based on our understanding of the technology, we decided that we could add additional tracks of tape to both deposition chambers of the multi-roll reel-to-reel evaporation system to increase overall throughput.

The result

The company’s upgraded system now has a 25% increase in system throughput.

Improving Heater Design for the University of Leeds

The challenge

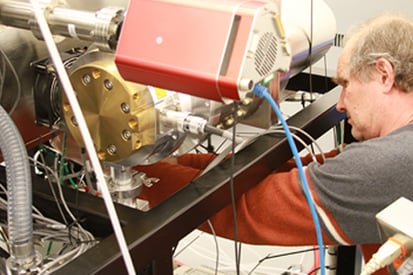

The University of Leeds had developed a unique laser implantation process for glass materials using femtosecond (fs) pulsed laser deposition (PLD) on heated glass substrates. With the idea to use the technology to detect counterfeit products, a large corporation required the university to demonstrate the implantation of telluride materials into the side wall of a large glass liquor bottle. To have the capability to do this, the university required a new heater design. The researchers came back to the PVD team to upgrade their heater.

The approach

We addressed this need by designing and building a completely unique heater, which we retrofitted into the university’s PLD system. The upgrade enabled the research team to use their existing laboratory system to test the experimental implantation process on a commercial product.

The result

The tests results were favorable. The success justified further funding, allowing the University of Leeds to purchase a large-area femtosecond PLD tool. The new equipment will allow the researchers to explore similar anti-counterfeit applications.

Added Load Locks for Stanford University & Purdue University

The challenge

Researchers at Stanford and Purdue came to PVD because their existing systems’ throughput was hampered by long pump-down cycles. They recognized that adding load locks would also entail considerable reworking of the control software.

The approach

During the design and implementation of the new load locks, PVD’s engineers developed new control software that could be integrated with the universities’ existing tool controls. The new features required training before use, so we hosted on-site orientation at both universities.

The result

Researchers at both universities can now run about 4x as many samples per day with the load locks in these systems.

The above case studies demonstrate situations where our scientific expertise enabled us to aid our customers in unique ways. We build custom systems that are designed to grow with your demands, addressing new problems specific to your evolving goals. It’s a capability that sets us apart from other deposition suppliers. If your needs require a specialized solution, we are a good fit for you.

To discuss system options and upgrades, send us your specs today.

Leave a Comment