The PLD/MBE 2300 and 2500 systems are larger versions of the PLD/MBE 2100 system. These larger systems are based around a 304L SS chamber that is 18 inches in diameter and 16 inches high.

The chamber includes an electric hoist to allow easy access to the internal parts of the chamber. The PLD/MBE 2300 had three 6” CF ports on the back wall for adding up to three additional sources. The PLD/MBE 2500 has four 4.5” CF ports and one 6” CF port on the back wall for adding up to five additional sources and is made mostly for the addition of effusion cells. The 6” ports on the 2300 and 2500 chambers can take magnetron sputtering sources, atom or ion sources, or effusion cells.

The chambers include a number of flanges for viewing the target, substrate, and ablation plume as well as additional accessories such as HP RHEED, emission spectroscopy, pyrometery, residual gas analyzers, etc.

Inside a UHV PLD/MBE 2300 system showing one UHV magnetron sputter source and one Kaufmann ion source

The PLD/MBE deposition system comes with a wide variety of options, including:

The PLD/MBE 2300 and 2500 chambers are mounted on a steel support frame with an electronics rack and aluminum tabletop that supports an integrated optical train. A second frame that includes a pair of standard electronic racks houses additional system electronics. This frame also serves as the support table for the excimer laser, providing a compact layout. Other types of lasers can be accommodated as well.

The chambers are cylindrical in design and include a set of internal shields for easy cleaning of walls from material build up, along with a variety of ports for PLD and other deposition technologies.

The PLD/MBE 2300 and 2500 each comes with a target manipulator that handles six 2-inch diameter targets. Targets are held in pedestals by gravity so target clamping or silver paste is not required. Smaller 1-inch diameter targets or other small sizes can easily be accommodated with optional inserts. The target manipulator is based on a pair of Ferro fluidic rotary feedthroughs that provide programmable target rotation speeds up to 50 RPM, programmable target indexing, and target toggling for enhanced use of target material. This robust Ferro seal feedthroughs provide extended lifetime when compared with bellows-sealed target manipulators that fail due to fatigue of the feedthrough due to excessive target motion.

All PLD/MBE systems come with a complete optical train, with kinematic mirror mounts and programmable laser beam rastering. Laser beam rastering, developed by Dr. Greer in 1987, provides excellent film thickness and target utilization. The optical trains are enclosed in laser-safe enclosures with a hinged door with laser interlock. It includes a pneumatic actuator that will open and close the excimer laser shutter via computer control. All chamber viewports include true UV grade blocking viewport covers for laser safety.

Back side view of a PLD/MBE 2500 system at University of Nebraska, courtesy of Dr. Christian Binek

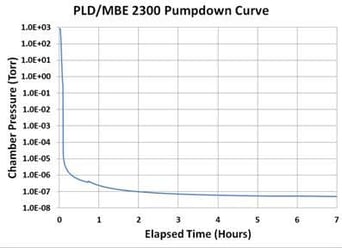

Standard systems include a single MFC, and additional MFCs are easily added on as needed. Vacuum gauging includes a Bayard Alpert ion gauge, two Convectron gauges, and a heated capacitance manometer. The base pressure of the system is 5 x 10-7 Torr standard, 5 x 10-8 Torr with optional load lock, and below 5 x 10-9 Torr with optional UHV package.

The rear of the PLD 2300 chamber is fitted with three angled 6.00-inch CF ports aimed at the substrate for the addition of up to three UHV magnetron sputter sources, or atom and ion sources, and/or effusion cells. With these three ports you can provide any mix of sources.

The PLD/MBE 2500 chamber includes four 4.5-inch CF flanges and one 6-inch CF flange, all directed at the substrate for holding up to five effusion cells and atom sources, or four sources with one magnetron sputter source, ion source, etc. The chambers include an internal light to provide excellent viewing of samples, target, and substrate transfers via our optional dual-wafer load lock. The chambers also include a set of internal SS shields that can be easily removed for cleaning when ablated material build-up becomes significant on the side walls. Furthermore, the PLD/MBE system's turbo pump mounts to the side of the chamber, protecting the pump from small parts or samples that may be inadvertently dropped in the system.

The chambers have a large top flange that seals against the chamber flange by a pair of Viton O-rings. For UHV applications, the gap between the Viton O-rings can be differentially pumped.

Inside a UHV PLD/MBE 2500 system showing five effusion cells and Staib high pressure RHEED gun and RHEED screen

Inside a UHV PLD/MBE 2500 system showing five effusion cells and Staib high pressure RHEED gun and RHEED screen

Photograph of the inside of a UHV PLD/MBE 2300 system showing two optional UHV magnetron sputter sources

The optical train also includes a PVD Products Intelligent Window developed by Dr. Greer in the early 1990’s. It includes a high quality AR coated window (usually for 248 nm (KrF)) for the beam to enter the vacuum chamber. An internal UV grade fused silica disc 197 mm in diameter is housed in a pair of flanges mounted on the PLD/MBE-2300 or 2500. An aperture is positioned on the target side of the disc. This defines a section of the disc that allows laser radiation to pass down to the targets and the area of the disc that will collect stray ablated target material. When the local section of the disc becomes sufficiently coated with ablated target material the disc can be easily rotated to a clean location to increase the fluence on the target. The discs are easy to clean, and a spare disc is included. Besides keeping the window clean for extended periods of time, the window also allows the user to insert a beam splitter in the path of the laser beam to reflect the laser radiation out of the chamber to a joule meter. This way, the energy that has traversed the entire optical train can be measured and adjusted to provide accurate and reproducible results from run to run. This approach to handling the laser entrance window coating is much more effective than swapping out the window every two or three runs as required on competitors' tools.

A water-cooled plate sits directly above the PLD targets and includes a removable cover that will expose a single target at a time for fast target transfers through a quick-access door located on the side of the chamber. The plate includes a slot for the laser beam to raster across the active rotating target and for the plume to expand out towards the substrate. The plate is sealed via VCR fittings and is fully UHV compatible. This plate protects the other targets from cross-contamination and protects the target manipulator assembly’s gears and bearings from thermal radiation emanating from the substrate heater.

The PLD/MBE 2300 and 2500 systems come with an IR lamp based heater capable of heating silicon and other non-transparent substrates to 950°C and transparent substrates to 850°C. (Note: PVD is quoting substrate temperatures, not heating element temperatures as there is a large difference in temperature between the element and the substrate on all heaters.) The heater can handle 2-inch diameter substrates or multiple smaller samples per the customer requirements (e.g. a holder for four 1-cm square samples). Using a Ferro fluidic rotary feedthrough, substrates can be rotated via computer at rates up to 40 RPM. The heater is typically mounted to a large motorized Z-stage, providing computer-controlled target-to-substrate distances varying from about 50 to 100 mm. The open architecture of our IR lamp heater is ideal for in-situ analysis using HP RHEED, and alternative deposition sources such as magnetron sputtering, effusion cells, ozone generators, atom or ion sources, etc. As noted, a variety of these deposition sources can be mounted on multiple flanges of the PLD/MBE 2300 or 2500 systems.

A PLD/MBE style non-contact substrate heater with programmable substrate rotation and pneumatic shutter assembly (optional RF bias is readily available)

The system includes a VAT Series 642 closed-loop gate valve with an integrated pressure controller to provide rock-steady deposition pressures from 1 to 500 mTorr. The PLD/MBE 2300 and 2500 systems include a Pfeiffer HiPace 700 turbo pump backed by a dry scroll pump. Standard systems include a single MKS digital MFC, and additional MFCs are easily added as needed. Vacuum gauging includes a Bayard Alpert ion gauge, two Convectron gauges, and a capacitance manometer. The base pressure of the system is 5 x 10-7 Torr standard, 5 x 10-8 Torr with optional load lock, and below 5 x 10-9 Torr with optional UHV package.

PLD/MBE 2300 Pump down curve versus time. A pressure of below 5 x 10-7 Torr is reached in about 50 minutes