PVD Products' standard systems come in two types of chambers, a box-style chamber or a cylindrical chamber. These chamber styles lend themselves to the use of removable internal shields for easy cleaning. PVD Products does not use spherical chambers (as used by several competitors) for deposition, as these make it very difficult to clean the deposited material that builds up on the chamber walls.

All of our box chambers are bolted to support frames that include casters and leveling pads. The frames can include either one or two standard 19-inch wide racks to house the various electronic components and also serve as the optical train and laser support table.

This photo displays the view of a PLD-3000 box-style chamber with the main door opened. Note the dual set of Viton O-rings, which are differentially pumped to yield a base pressure below 5 x 10-9 Torr. A set of reflecting shields on the heater body has been removed to expose the substrate spinner assembly, which has been lowered to the substrate exchange position. Note that the black-body style substrate heater includes a complete water-cooled housing unit. Also seen is one of three target pedestals which are exposed by simply removing a cover plate. Targets can be easily changed through this cutout without removal of any flanges. Also seen in this figure is a shutter used for pre-cleaning targets as well as the target manipulator gear set and bearing carousel.

Inside the box-style deposition chamber

This photo displays the view of a PLD/MBE-2100 cylindrical chamber with the top flange lifted via an electronic hoist. Note the dual set of Viton O-rings, which are differentially pumped to yield a base pressure below 5 x 10-9 Torr. These systems include high temperature lamp-based heaters mounted to the top flange. Seen is the top of the target manipulator that includes six 2-inch diameter targets. Targets can be easily changed through a cutout without removal of any flanges. Also seen in this figure is a single UHV 2-inch magnetron sputter source.

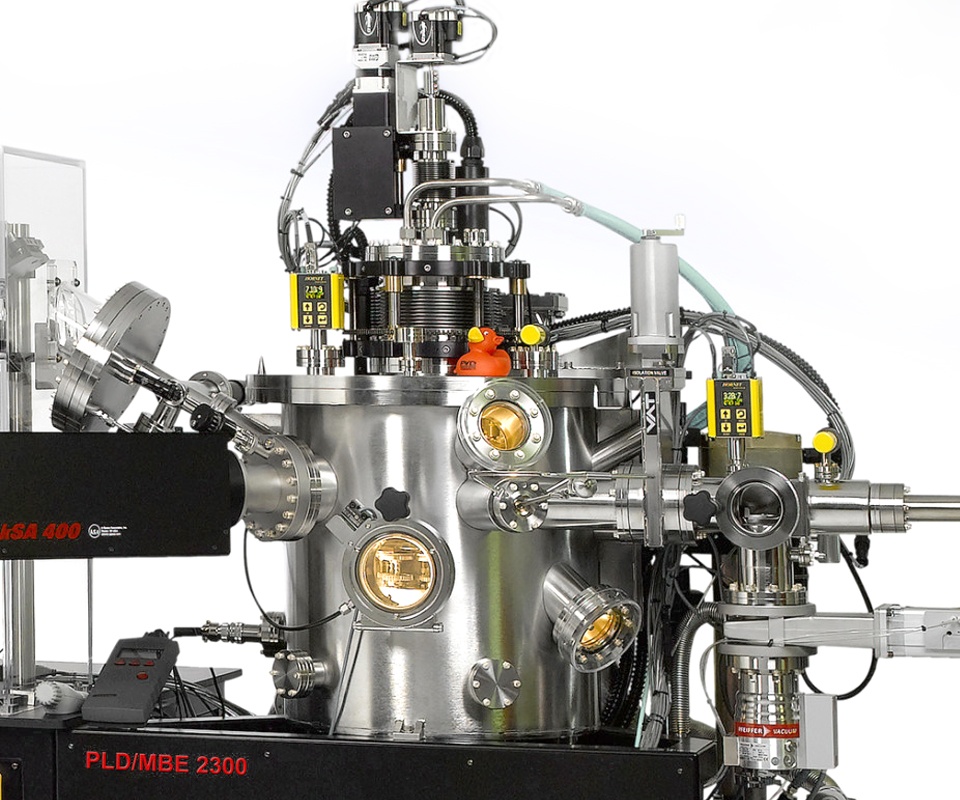

Our cylindrical chambers are also frame mounted, with electronic racks that support the optical train and laser as well as the power distribution box.

Inside the cylindrical-style deposition chamber