PVD Products manufactures complete integrated sputtering systems to meet your specific deposition requirements. These systems can be configured with multiple RF and/or DC magnetron sources ranging in size from 1 inch (25 mm) to 8 inches (200 mm) in diameter. We can provide systems to handle wafers up to 300 mm in diameter, heating up to 900°C, and RF bias with additional ports for diagnostics such as Reflection High-Energy Electron Diffraction (RHEED), ellipsometry, and Multi-beam Optical Sensors (MOSS) for in-situ stress measurement.

UHV sputtering and evaporation system for 4-inch wafers with heating to 850°C, RF bias, three UHV magnetrons with in-situ tilt, and three-pocket UHV e-beam source. Located at NIST, Boulder CO.

UHV sputtering and evaporation system with HP RHEED and in-situ ellipsometry. Includes a 4-inch wafer holder with heating to 850°C with RF bias, three 2-inch UHV magnetrons with in-situ tilt, and three-pocket UHV e-beam source.

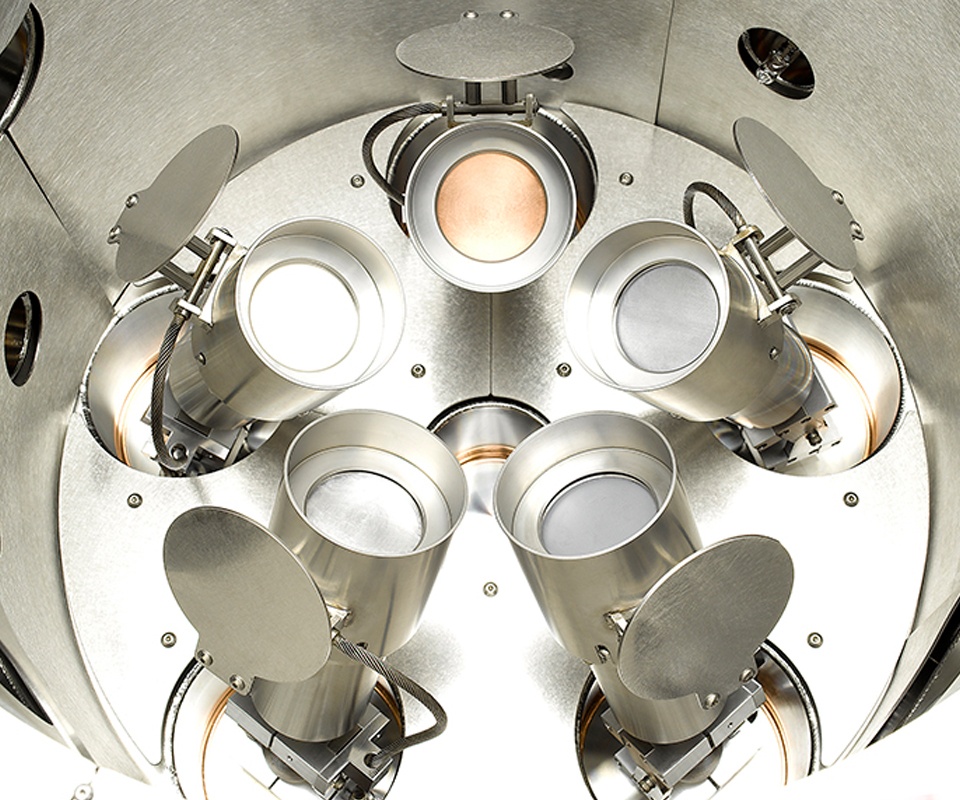

Sputtering chamber for a 4” diameter wafer which can be heated to 850°C with RF bias, loadlock, and six 2” magnetrons with manual in-situ tilt.

Sputter-down system for 4-inch diameter substrates with RF bias, load lock, and four 2-inch magnetrons.

Our Titan Magnetrons can be operated with DC, pulsed DC, or RF power. Magnetron systems with multiple sources can be supplied with single power supplies and switching networks, or with multiple supplies for co-deposition processing.

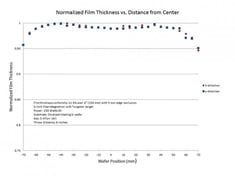

The graph below shows the film thickness uniformity of ±2.5% obtained over a 6-inch (150-mm) substrate with 5-mm edge exclusion using a 3-inch Titan Magnetron and W target. The film was deposited at 250 Watts DC onto an oxidized rotating Si wafer in 5 mTorr Ar, using a target-to-substrate distance of 6 inches. Measurements were made via a 4-point probe in two mutually perpendicular directions (X, Y) across the wafer surface.

PVD Products has unique in-house expertise for integrating vacuum, plasma, and thin film diagnostics in the magnetron sputtering chamber. These diagnostics include Residual Gas Analyzers, RHEED, ellipsometry, Optical Emission Spectroscopy (OES), and Multi-beam Optical Sensors (MOSS) for in-situ stress measurement. In addition, auxiliary ion beam sources using DC or RF style Kaufmann ion sources and End Hall sources can be provided for direct ion beam deposition or Ion Beam Assisted Deposition processing.

Magnetron sputtering chambers are available in either cylindrical or rectangular geometries and sputter-up or sputter-down configurations. Rectangular chambers are designed with a hinged door to provide easy access to the chamber interior. Cylindrical chambers are accessed through a large flat flange that is lifted from the chamber via an electric hoist. The Viton O-ring seals are differentially pumped to achieve pressures as low as 1 x 10-9 Torr. All chambers are supplied with a set of internal 304 Stainless Steel shields that are easily removed for periodic cleaning of excessive film deposits.

Up to six magnetron sources are mounted on separate ConFlat flanges arranged in a confocal array where each source is directed at a point slightly above the substrate target and at an angle of roughly 30 degrees from the substrate normal for optimal deposition uniformity.

With the load lock option, the main chamber base pressure is guaranteed to be below 1 x 10-9 Torr. Load locks are available for substrates up to 8 inches (200 mm) in diameter. The load lock assembly includes a pneumatic roughing valve and turbomolecular pump with its own pneumatic gate valve. Our dual-wafer load lock allows the customer to transfer one wafer into the chamber and remove one wafer from the chamber in one pump down cycle. This greatly reduces the cycle time compared to competitors' single-wafer load locks.

PVD Products offers systems that combine various Physical Vapor Deposition technologies in a single chamber. For example, magnetron sputtering can be combined with evaporation using either thermal or e-beam evaporation sources.

Substrate planetary or rotation stages provide substrate heating to temperatures in excess of 900°C with RF or DC Bias. Substrate heaters and manipulators can be designed for non-standard substrate shapes and sizes.

Magnetron sputtering systems may be pumped by either a cryogenic or turbomolecular main pump depending on the customer’s process conditions. A dry backing pump and electro-pneumatic valving are computer controlled to provide automatic rough pumping of the main chamber and backing of the main pump. A stepper motor controlled gate valve is used to isolate the chamber from the pumping system and provide closed-loop control of the chamber pressure when integrated with a capacitance manometer and pressure controller.

The magnetron sputtering system is computer controlled through a LabVIEW interface and Opto-22 PLA control unit. A laptop computer is mounted on an articulated arm for easy access. All valves and shutters on the system can be open/closed in a step-by-step mode from the computer with safety interlocks. Auto pump/vent sequences are provided for the load lock and main chamber. All relevant process parameters for the vacuum chamber and load lock, gas handling, magnetron power supplies, and substrate stage are monitored and controlled by the LabVIEW software. Depositions from a single source or co-deposition from multiple sources are possible. Deposition recipes can be created, stored, edited, and recalled by users depending on their system access authority.

"PVD is genuinely interested in helping me advance my capabilities for thin film deposition with an instrument that fits my applications best."